Industrial Coffee Grinder for Mass Brewing: What You Need to Know

Industrial Coffee Grinder for Mass Brewing: What You Need to Know

Blog Article

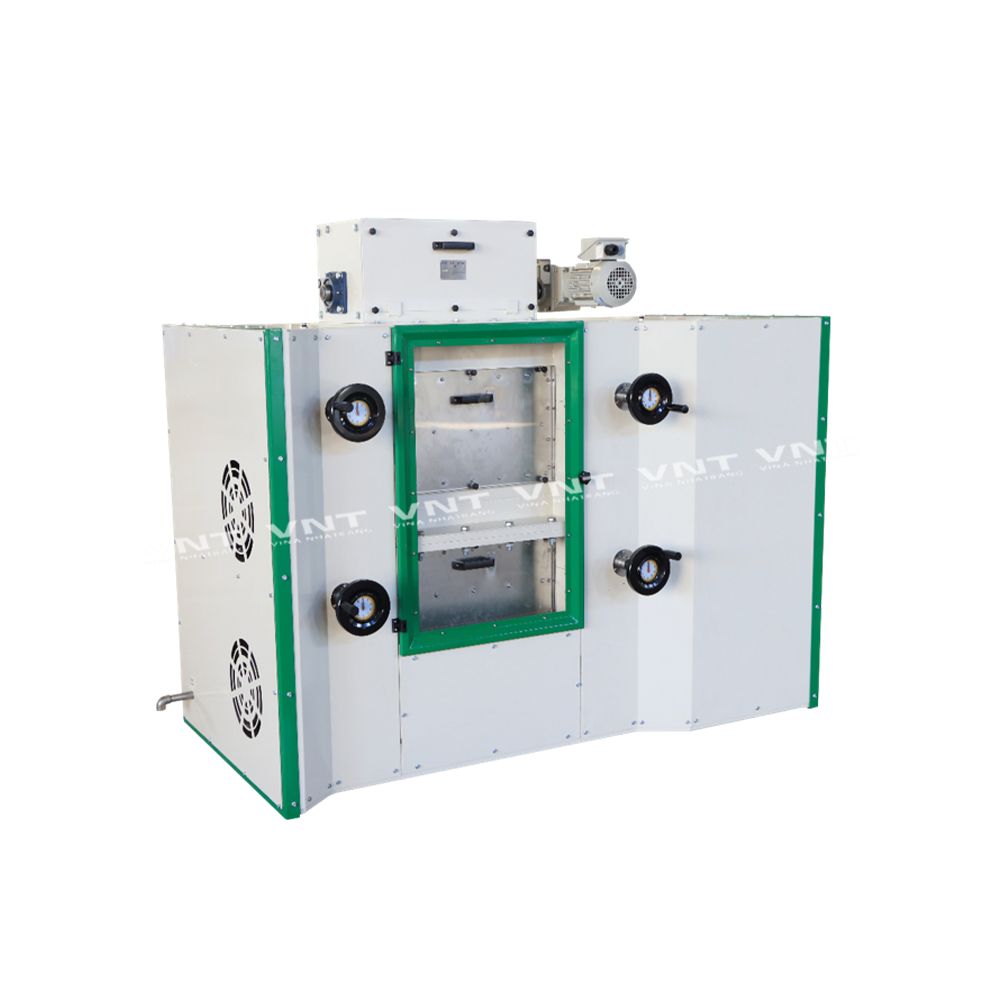

Industrial Coffee Mill Guide: Boost Effectiveness and Quality

In the competitive landscape of coffee manufacturing, selecting the best industrial coffee grinder plays a critical duty in enhancing both efficiency and item quality. Understanding the nuances of different grinder types and essential functions-- such as adjustable work setups and durable construction-- can dramatically affect the last flavor profile of the coffee.

Understanding Grinder Kinds

When picking a commercial coffee mill, understanding the different types available is vital for enhancing both taste removal and operational efficiency. The two primary sorts of mills are blade mills and burr grinders. Blade grinders utilize sharp blades that cut coffee beans right into inconsistent dimensions, bring about unequal extraction and possibly unwanted flavors. While blade mills are commonly much more inexpensive and suitable for small-scale procedures, they are normally not recommended for industrial use.

Inevitably, choosing the right sort of mill is important to keeping quality and performance in coffee production, making it vital for businesses to invest in premium burr grinders for ideal outcomes.

Key Functions to Think About

Picking an industrial coffee grinder calls for mindful consideration of several crucial attributes that can considerably affect both efficiency and the overall coffee experience. One of the main facets to evaluate is the grinding mechanism. Burr mills are typically favored over blade mills, as they provide a consistent work size, which is critical for optimum extraction and flavor.

An additional vital function is the grinder's capability. Relying on the volume of coffee you require to process, select a design that can manage your demands without compromising rate or high quality. Furthermore, consider the grind settings provided. A flexible grinder with multiple settings allows you to tailor the work dimension to different brewing methods, enhancing the coffee's flavor account.

Evaluate the mill's noise level, especially in a busy coffee shop or production atmosphere, where extreme sound can be disruptive. Spending in a grinder that stabilizes these functions can significantly boost both operational performance and the quality of the coffee served.

Optimizing Grinding Refine

To attain the best results in coffee preparation, maximizing the grinding procedure is vital. The work dimension considerably influences extraction, flavor, and total high quality of the made coffee.

In addition, keeping track of the grinding speed can enhance the process. Slower grinding frequently produces less warm, protecting delicate flavors and aromas. On the other hand, quicker grinding might produce extreme warm, negatively affecting the coffee's top quality.

Upkeep and Treatment Tips

Appropriate upkeep and care of industrial coffee grinders are important for guaranteeing optimal performance and longevity. Regular cleaning is the structure of upkeep; residue buildup can impact flavor and grinding efficiency. It is advisable to clean the mill after each usage, cleaning down the exterior and removing any coffee premises from the burrs.

Furthermore, check the grinding burrs for deterioration. Boring burrs can compromise work consistency, so they should be replaced as essential. Industrial Coffee Grinder. Occasionally calibrating the grinder is additionally important, as this keeps the wanted grind dimension for different brewing approaches

Lubrication of relocating parts should be executed according to the producer's specifications, as this lowers rubbing and prolongs the life of the tools. It is important to use food-grade lubricants to make sure safety and compliance with health policies.

Lastly, maintain the grinder in a steady and dry setting to avoid rust and deterioration. By adhering to these upkeep and treatment tips, drivers can boost the efficiency of their commercial coffee mills while guaranteeing premium result and extended functional life.

Return on Financial Investment Evaluation

Assessing the return on financial investment (ROI) for commercial coffee mills is vital for companies seeking to enhance their coffee manufacturing capacities. A complete ROI analysis aids establish the financial viability of investing in top notch mills, allowing businesses to weigh the initial expenses against prospective gains.

Evaluate the acquisition cost of the grinder, consisting of setup and any have a peek at these guys essential adjustments to existing infrastructure. High-performance mills commonly lead to reduced grinding time and increased throughput, which can dramatically improve productivity.

In addition, think about the influence on item high quality. Industrial Coffee Grinder. Superior mills produce an even more constant grind dimension, which can enhance taste profiles and consumer fulfillment, eventually driving sales. By increasing the high quality of the end product, businesses can warrant greater pricing, causing increased profits

Conclusion

In summary, an industrial coffee mill plays an essential duty in enhancing both performance and product top quality within coffee production. By choosing top quality burr mills equipped with vital functions such as flexible grind settings and sturdy construction, services can guarantee optimal taste removal. Normal maintenance is essential for sustaining grinder performance and making best use of customer fulfillment. Inevitably, the tactical investment in a trustworthy grinder adds over here significantly to helpful site improved earnings and competition in the coffee market.

In the affordable landscape of coffee production, choosing the right commercial coffee mill plays an essential function in improving both efficiency and item top quality. The 2 main types of grinders are blade mills and burr grinders. Within the burr grinder category, there are level burr mills and cone-shaped burr grinders, each with its benefits. Burr grinders are generally preferred over blade mills, as they offer a consistent work dimension, which is essential for optimal extraction and taste.

In recap, an industrial coffee mill plays a crucial function in enhancing both efficiency and item quality within coffee production.

Report this page