Industrial Coffee Grinder: Important Qualities to Consider When Shopping

Industrial Coffee Grinder: Important Qualities to Consider When Shopping

Blog Article

Industrial Coffee Mill Overview: Increase Efficiency and Quality

In the competitive landscape of coffee manufacturing, choosing the right commercial coffee mill plays a pivotal duty in boosting both efficiency and product top quality. Comprehending the subtleties of numerous grinder kinds and essential attributes-- such as personalized work settings and durable building-- can dramatically affect the final taste account of the coffee. The optimization of the grinding procedure, combined with thorough upkeep, is essential for maintaining efficiency over time. As we check out these crucial aspects, it ends up being obvious that the effects extend past plain tools selection, impacting total service success in methods that call for closer examination.

Recognizing Mill Kinds

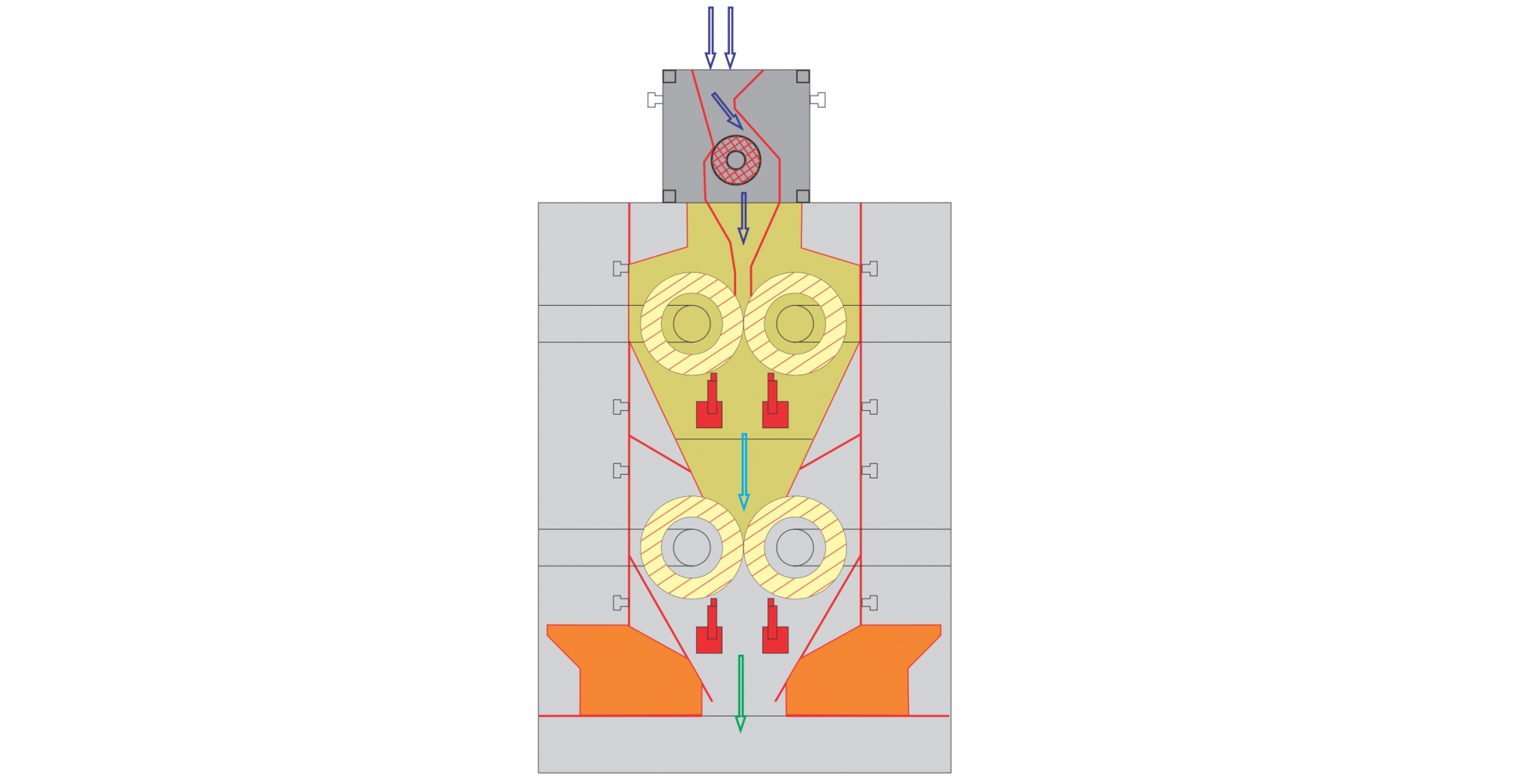

When picking an industrial coffee grinder, comprehending the numerous types readily available is important for enhancing both taste extraction and operational performance. The 2 key types of grinders are blade mills and burr grinders.

Eventually, selecting the right kind of mill is integral to preserving top quality and efficiency in coffee production, making it necessary for businesses to purchase high-grade burr mills for optimum results.

Key Functions to Think About

Picking a commercial coffee mill needs careful consideration of several crucial features that can considerably affect both efficiency and the total coffee experience. One of the key aspects to assess is the grinding device. Burr mills are typically chosen over blade grinders, as they give a regular work size, which is vital for optimal removal and flavor.

One more essential feature is the grinder's ability. A flexible grinder with multiple setups enables you to tailor the grind size to various brewing techniques, boosting the coffee's taste profile.

Assess the grinder's sound level, especially in a hectic coffee shop or manufacturing environment, where too much sound can be turbulent. Spending in a grinder that stabilizes these attributes can significantly boost both functional effectiveness and the quality of the coffee offered.

Optimizing Grinding Refine

To accomplish the most effective outcomes in coffee preparation, enhancing the grinding process is crucial. The work size substantially affects extraction, taste, and general top quality of the brewed coffee. Different developing techniques require specific grind sizes; for example, espresso requires a fine work, while French press requires a crude structure. Comprehending the connection between work size and brewing technique is the very first step in optimization.

Additionally, checking the grinding rate can optimize the process. Slower grinding often generates much less warm, protecting delicate flavors and scents. Alternatively, quicker grinding might create extreme heat, negatively influencing the coffee's high quality.

Maintenance and Care Tips

Correct upkeep and treatment of commercial coffee grinders are essential for making sure optimum efficiency and long life. Routine cleansing is the foundation of maintenance; deposit accumulation can impact taste and grinding efficiency. It is advisable to clean up the grinder after each usage, wiping down the exterior and removing any type of coffee premises from the burrs.

Additionally, examine the grinding burrs for deterioration. Boring burrs can jeopardize work uniformity, so they should be replaced as necessary. Industrial Coffee Grinder. Regularly calibrating the grinder is also essential, as this keeps the desired grind dimension for different developing techniques

Lubrication of relocating parts need to be performed according to the manufacturer's specs, as this decreases friction and lengthens the life of the devices. It is vital to make use of food-grade lubricating substances to make sure safety and conformity with health and wellness policies.

Finally, keep the mill in a dry and secure environment to avoid corrosion and navigate here rust. By sticking to these upkeep and treatment tips, drivers can enhance the performance of their industrial coffee mills while making sure premium output and prolonged functional life.

Return on Investment Evaluation

Assessing the return on financial investment (ROI) for industrial coffee grinders is essential for organizations looking for to maximize their coffee production abilities. A complete ROI evaluation helps identify the financial feasibility of purchasing top notch mills, permitting companies to consider the initial costs versus prospective gains.

Examine the purchase cost of the grinder, consisting of installation and any necessary adjustments to existing framework. High-performance mills you could try this out often lead to minimized grinding time and increased throughput, which can dramatically boost performance.

Additionally, consider the impact on product quality. Industrial Coffee Grinder. Superior mills produce a more constant work size, which can boost taste profiles and consumer satisfaction, eventually driving sales. By raising the top quality of the end product, businesses can warrant greater prices, bring about boosted income

Verdict

In summary, a commercial coffee grinder plays a critical duty in enhancing both performance and item quality within coffee production. By picking top quality burr grinders geared up with necessary functions such as adjustable grind setups and resilient building, businesses can make sure optimum taste extraction. Moreover, routine maintenance is essential for sustaining mill efficiency and optimizing client fulfillment. Ultimately, the strategic financial investment in a dependable mill contributes considerably to improved income and competitiveness in the coffee market.

In the affordable landscape of coffee production, picking the right industrial coffee grinder plays an essential function in boosting both efficiency and product quality. The 2 main types of grinders are blade mills and burr mills. Within the burr grinder group, there are level burr grinders and conical burr mills, each with its benefits. Burr grinders are normally preferred over blade grinders, as they offer a constant work size, which is essential for optimum extraction and taste.

In recap, an industrial coffee mill plays an essential function in boosting both efficiency and item quality within coffee production.

Report this page